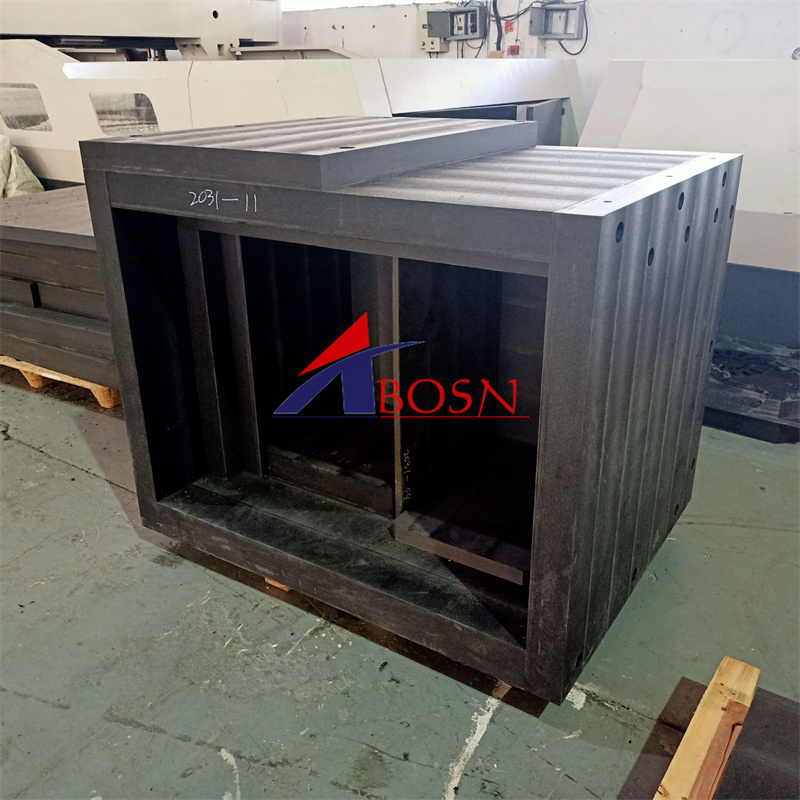

Machining method of lead boron polyethylene radiation protection shield

The lead-boron-polyethylene radiation protection shield for nuclear reactors is mainly used for shielding the comprehensive radiation field of neutrons and gamma rays. For nuclear reactors that require small size and light weight, this material cannot be used to make protective shields. At present, lead boron polyethylene is mainly used as the material for the radiation protection shield.

The traditional machining methods of lead-boron polyethylene radiation protection shields are:

The first step, the lead boron polyethylene sheet to be added is set out according to the drawing, including the shape line, the drilling position line, etc.;

The second step is to place the board that has been set out and marked on the drilling machine to drill the connection holes;

The third step is to connect and assemble the drilled plates according to the size requirements of the processing drawings to form workpieces for turning and milling;

The fourth step is to draw the position line of turning and milling on the assembled workpiece;

The fifth step is to mill out the lap joint of the assembled workpiece that meets the size of the drawing on the milling machine;

The sixth step is to clamp the workpiece on a vertical lathe whose specifications meet the requirements of the work piece, and segment the inner and outer diameter surfaces of the assembled work piece to make it meet the cylindrical surface section required by the design drawings; due to the machining allowance of the workpiece If it is large, the inner and outer diameters must be rough and finely machined; moreover, the weight of the workpiece is 160~800 kilograms, so it is difficult to align;

The seventh step is to bore the vias and pipeline vias used for the maintenance of the radiation protection shielding body;

In the eighth step, the work piece processed into the cylindrical surface section is assembled into a radiation protection shield. The disadvantages or problems of this processing method are

(1) There are manual markings, and the alignment accuracy and processing accuracy are not high;

(2) Large-scale equipment is required for the milling interface and the inner and outer diameters of the car to meet the requirements of the workpiece drawing, and the equipment investment is large;

(3) It is difficult to align during machining, because the weight of the workpiece is 500-800 kg;

(3) Since the component is a polymer composite material, the elastic and plastic deformation is large, and the clamping is difficult;

(4) Since the component is a polymer composite material, the elastic and plastic deformation is large, and it is difficult to clamp

(5) The accumulated error of repeated clamping is large, and the precision control is difficult;

(6) Tooling is required for turning processing, and the size and specifications are large, so it is difficult to find the correct tooling for reprocessing.

other related :

borated uhmwpe radiation shielding uhmwpe sheets

any more request ,contact with us freely.

email [email protected] whats app : 86-17553419326