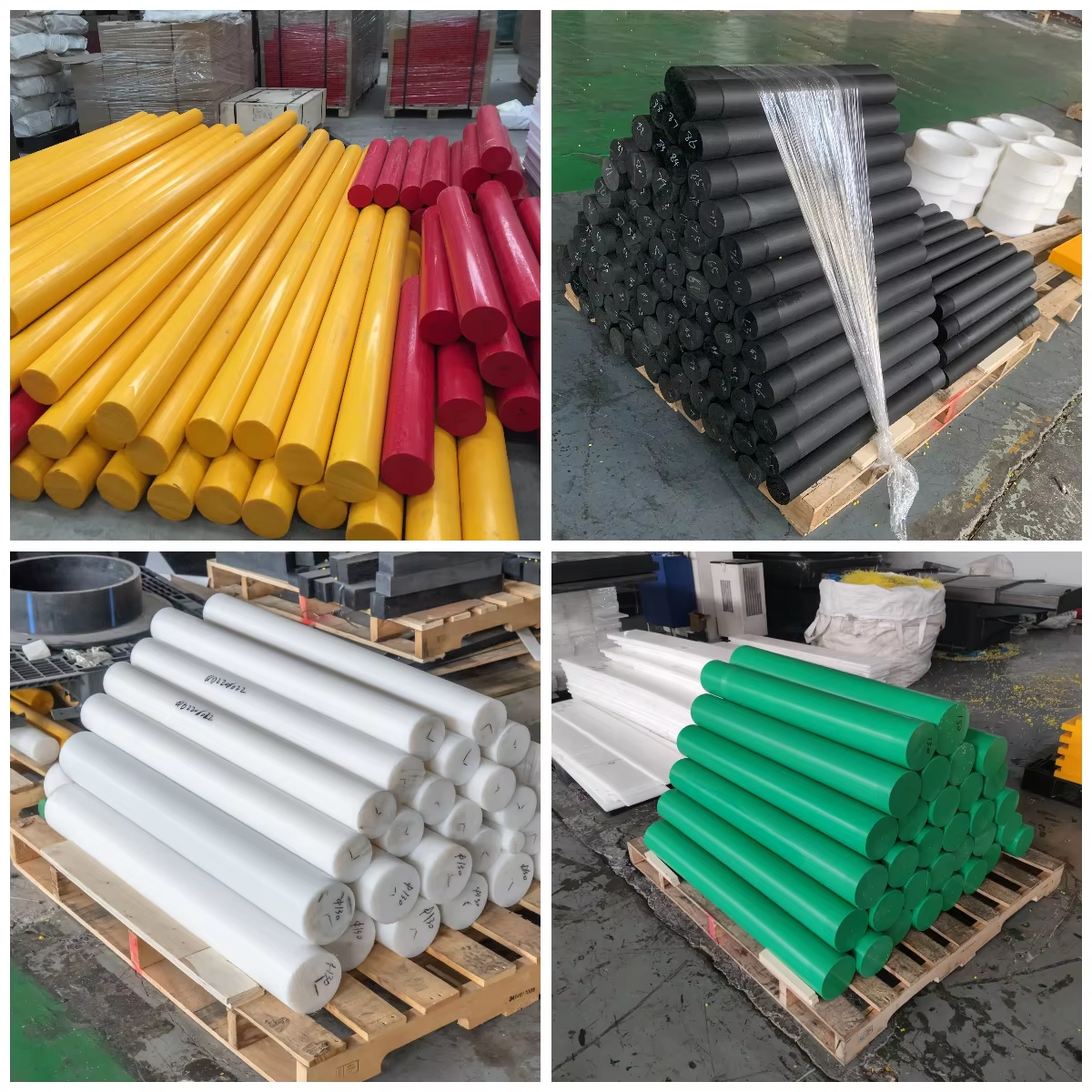

Natural plastic UHMWPE Solid round Bar/PE Solid Bar /HDPE Solid Bar /Polyethylene Solid Bar

Superior quality UHMWPE solid plastic bar extruding UHMWPE rod plastic rod

UHMWPE material has exceptionally low coefficient of friction offering superb sliding properties and is one of the best plastics for wear/abrasion resistance meanwhile tough and impact resistant even at cryogenic temperatures. As a result, it is definite that UHMW polyethylene is a wonderful engineering plastic that can solve many problems that other engineering plastics cannot.

Any size and color can be customized according to the clients' special needs!

Custom CNC Machining Parts Services

Quotation:According to your drawing(size,material,thickness,processing content,and required technology,etc)

Processing equipment:CNC lathe, CNC milling machine, drilling machine

Core machine, Cutting machine

Accept drawings:CAD (DXE.DWG), PDF, Pro/Engineer

Delivery time:3-5 days for samples, 2-3 weeks for mass production

1.Abrasion resistance

2.High energy absorption

3.Impact resistance

4.Zero water absorption

5.Chemical resistance

6.Excellent temperature property

7.High tensile strength

8.UV-resistant

10.good tensile strength

11.good impact intensity

12.super compression strength

13.good breaking elongation

14.Percent the weight of steel pads

15.Chemically inert, serviceable from 180° F to - 250° F

16.Corrosion, chemical, wear and moisture resistant.

17.Non-stick surface, easy to clean